Lighting accounts for up to 20% of global electrical energy consumption. At an organizational level, lighting can account up to 40% of total energy use. The chances are that a lot of this energy is being wasted. To improve on energy efficiency, one of the key areas to address is lighting systems.

There has been significant advancement in lighting technology over recent decades, as organisations move towards more efficient forms of lighting. However, in many cases, lighting still suffers from significant energy-wasting problems. Incandescent bulbs, fluorescents tubes, compact fluorescents (CFLs) and metal halides have varying degrees of inefficiency; but in all cases have been superseded by Light Emitting Diode (LED) technology.

The range of LED lighting provides the same light, in the same fixtures, at often less than half the cost. Take a T8 for example. A T8 LED simply replaces a 35W standard fluorescent tube and produces the same amount of light while only using 18W of electricity. As soon as the switch is turned back on, a 50% reduction in energy consumption is achieved.

The LED runs cooler than the traditional fluorescent tube and so, if that area is air-conditioned, climate control costs can also be reduced by 5%. The fluorescent tube will in most cases burn out after 10,000 hours. The LIBROS LED lighting has a working life of over 50,000 hours saving the cost of replacement tubes and labour costs for maintenance.

Lighting accounts for up to 20% of global electrical energy consumption. At an organizational level lighting can account for up to 40% of total energy use. In order to improve energy efficiency in lighting systems, Lighting Controls are used across the globe to reduce energy consumption within commercial and institutional environments.

The Lighting Controls range include intelligent photocells, occupancy sensors and daylight harvesting sensors. In the right applications, savings of up to 50% are possible.

The demand for quality High-Bay lighting solutions remain strong; and as the price of hardware has come down simultaneously energy costs have continued to rise.There has been much advancement in lighting over recent decades, as organizations move towards more efficient forms of lighting.

However, in many cases, lighting still suffers from significant energy-wasting problems.Rooms left unoccupied continue to be lit long after occupants have left an area, wasting energy in the process.

Our Lighting Controls range introduces intelligence into existing lighting systems. The products include:

Our Lighting Controls are simple to install and will deliver phenomenal results every time with zero maintenance requirements.

Lighting Controls are perfectly suited for integration into High-Bay installations found in factories, retail parks, malls, arenas, car showrooms, exhibition malls, and hypermarkets.

The key benefits of Lighting Controls include:

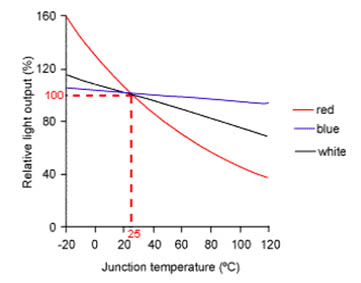

Prolonged heat can significantly shorten the useful life of many LED systems. Higher ambient temperature leads to higher junction temperatures, which can increase the degradation rate of the LED junction element, possibly causing the light output of an LED to irreversibly decrease over the long term at a faster rate than at lower temperatures.

This is why our manufacturer has developed enhanced thermal management systems to keep the junction temperatures low even in elevated ambient temperatures found in such places like power Houses, Boiler Rooms, Foundry Area, Steel smelting plants.

This is why our manufacturer has developed enhanced thermal management systems to keep the junction temperatures low even in elevated ambient temperatures found in such places like power Houses, Boiler Rooms, Foundry Area, Steel smelting plants.

They can also work in hazardous environments where there exists explosive gases such as in Oil & Gas or in High Pressure wash-downs such as in livestock farming, food processing and car parks environments. They meet IP 67 or IP 68 and can be used up to 65oC ambient temperatures.

The special LED lighting for extreme applications come with either 7 or 10 year warranty depending on the product

In general, the cooler the environment, the higher an LED’s light output will be. Higher temperatures generally reduce light output. In warmer environments and at higher currents, the temperature of the semiconducting element increases. The light output of an LED for a constant current varies as a function of its junction temperature.

The Figure below shows the light output of several LEDs as a function of junction temperature.

Keen to learn more about LIGHTING? There are many ways you can get in touch with our team. Simply contact us via phone, email or live chat and we would be happy to answer your questions.